The MAX6675 board and the TC are mounted into the roaster.

Here you can see the thermocouple in the roasting chamber.

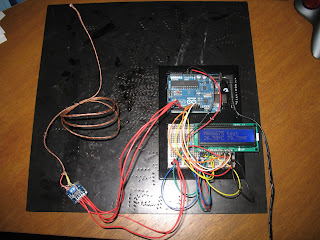

The small 5 volt wires were soldered and then topped with wire nuts. It was a bit of a trick to get it all wired and slid together.

I will run it through some tests today and make sure that everything is working. Then I can put the finishing touches on the roaster. As a side note, here is the color coding for the 5 volt wires.

Ground = Blue = -5vdc

VCC = Orange = +5vdc

DO = Green = Arduino Pin 4

CS = Brown/White = Arduino Pin 5

CLK = Brown = Arduino Pin 6